Switch to high-power UV LED curing for rapid, precise, and eco-friendly results. Learn key selection factors for your manufacturing needs

In modern manufacturing, efficiency and speed are paramount. Traditional UV curing methods can be slow, energy-intensive, and environmentally unfriendly. Enter high-power UV curing LED systems: a revolutionary technology that delivers rapid, precise, and sustainable curing for a wide range of applications. This blog delves into the benefits, applications, and key considerations when choosing a high-power UV curing LED system.

The Evolution of UV Curing: From Bulbs to LEDs

Traditional UV curing relied on mercury arc lamps, which generate significant heat, consume high energy, and contain hazardous materials. High-power UV curing LED systems offer a superior alternative, leveraging the advantages of LED technology:

- Energy Efficiency: LEDs consume significantly less energy than traditional lamps, reducing operating costs and environmental impact.

- Long Lifespan: LEDs have a much longer lifespan, minimizing downtime and maintenance costs.

- Precise Control: LEDs offer precise control over intensity and wavelength, enabling optimized curing for specific materials.

- Instant On/Off: LEDs turn on and off instantly, eliminating warm-up and cool-down times.

- Cool Operation: LEDs generate less heat, reducing the risk of damage to heat-sensitive materials.

- Environmentally Friendly: LEDs are mercury-free, eliminating the risk of hazardous waste.

High-Power Advantage: Speed and Performance

High-power UV curing LED systems take these benefits to the next level, delivering:

- Faster Curing Speeds: Higher intensity LEDs enable rapid curing, increasing production throughput.

- Deeper Curing: High power allows for deeper penetration of UV light, ensuring complete curing of thick coatings and adhesives.

- Uniform Curing: Advanced optics and LED arrays ensure uniform light distribution, resulting in consistent curing across the entire surface.

- Increased Productivity: Faster curing and reduced downtime translate to increased productivity and profitability.

Applications Across Diverse Industries:

High-power UV curing LED systems find applications in a wide range of industries:

- Adhesive Bonding: Rapid curing of adhesives in electronics, automotive, and medical device manufacturing.

- Coating Curing: High-speed curing of coatings on wood, plastics, and metal surfaces.

- Printing and Graphics: Instant curing of inks and coatings in digital printing and graphic arts.

- Electronics Manufacturing: Curing of conformal coatings, solder masks, and other materials in PCB assembly.

- Medical Device Manufacturing: Curing of medical adhesives and coatings in a controlled environment.

Key Considerations When Choosing a High-Power UV Curing LED System:

- Wavelength: Select the appropriate wavelength for your specific curing application.

- Intensity: Determine the required intensity to achieve the desired curing speed and depth.

- Curing Area: Choose a system with a curing area that matches your production requirements.

- Control System: Evaluate the system’s control capabilities, including intensity control, timing, and monitoring.

- Cooling System: Ensure the system has an effective cooling system to maintain optimal LED performance.

- Integration: Consider the system’s compatibility with your existing production line.

- Reliability and Support: Choose a reputable supplier that offers reliable products and comprehensive support.

The Future of Curing: Embracing LED Technology

High-power UV curing LED systems represent the future of curing technology. By offering superior performance, energy efficiency, and environmental friendliness, these systems are transforming manufacturing processes across industries. Investing in a high-power UV curing LED system can significantly enhance your production capabilities and give you a competitive edge.

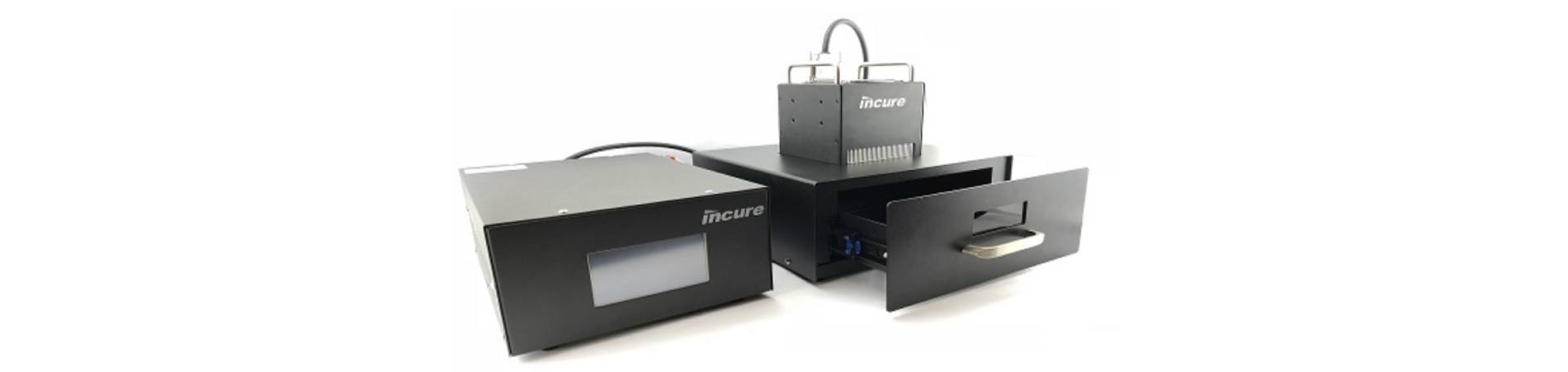

Contact Us, Incure’s authorized distributor for personalized recommendations on wavelength and cure times. Visit www.blazeasia.com to learn more.