UV Curable Optical Adhesives – INCURE

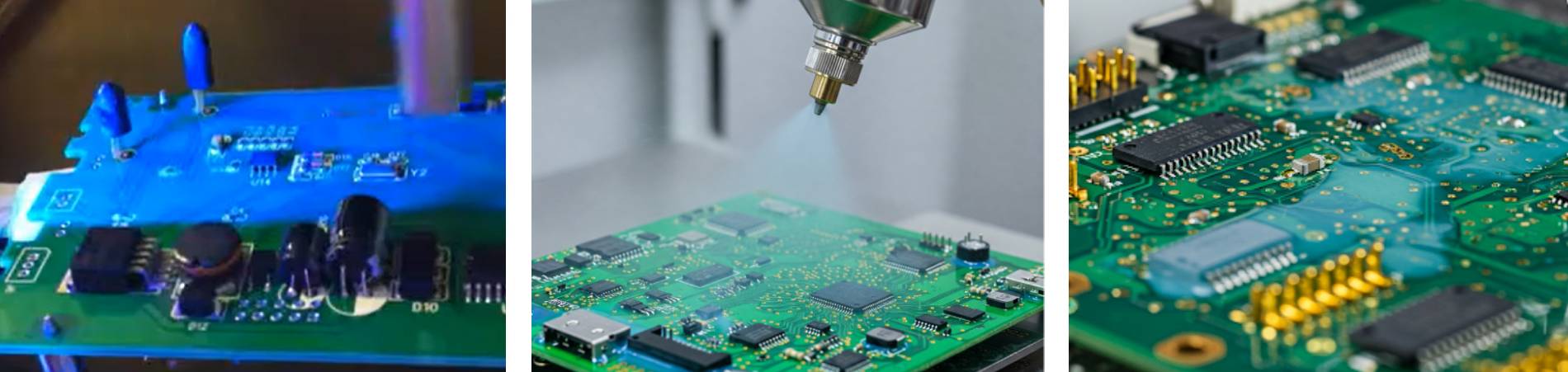

Modern manufacturing demands precision. UV optical adhesives offer rapid curing, precise bonding, and superior clarity, solving challenges with traditional adhesives.The Challenges of Modern Manufacturing Modern manufacturing demands precision, speed, and durability. Whether you're assembling intricate optical components, bonding delicate electronic devices, or creating robust medical instruments, traditional adhesives often fall short. They can introduce unwanted stress, require lengthy curing times, and compromise the overall quality of your products. Enter UV Optical Adhesives: A Revolution in Bonding UV optical adhesives offer a compelling solution to these challenges. These specialized formulations cure rapidly when exposed to ultraviolet (UV) light, providing a strong, transparent, and highly reliable bond. Key Benefits for Manufacturers: Rapid Cure Times: UV curing dramatically reduces production cycle times, allowing for faster throughput and increased efficiency. This is crucial for high-volume manufacturing environments. Precise Bonding: UV adhesives offer exceptional control over the curing process. You can precisely control the timing and location of the cure, minimizing stress and ensuring accurate alignment. Superior Optical Clarity: These adhesives are designed for optical applications, providing excellent transparency and minimal distortion. This is essential for applications involving lenses, prisms, and other optical components. High Bond Strength: UV adhesives create strong, durable bonds that can withstand demanding environmental conditions, including temperature fluctuations, humidity, and vibration. Versatility: UV optical adhesives can bond a wide range of substrates, including glass, plastics, metals, and ceramics. This versatility makes them suitable for diverse manufacturing applications. Reduced Waste and Environmental Impact: Precision application and rapid curing minimize waste and reduce energy consumption, contributing to a more sustainable manufacturing process. Improved Product Reliability: Consistent and reliable bonding leads to higher product quality and reduced failure rates, enhancing customer satisfaction. Incure Optik™ Series Core Products Product Description Substrates Color Viscosity (cP) Tensile Strength (psi) Hardness (Shore D) Elongation (%) 7063 Tack-free curing with up to 5,400 PSI on metals, glass, and ceramics. Very low linear shrinkage with enhanced moisture and temperature resistance. Offers good passive vibration isolation. Metal/Glass/Ceramics Clear 700 4,400 - 5,400 59 - 69 400 7210 Ultra-low linear shrinkage for precise optical positioning. Excellent passive vibration resistance. Bonds strongly to glass, metals, ceramics, and plastics. Ideal for optical device sealing and alignment. Multi-Substrates (High Strength Plastics) Slight Yellowish Tint 80 2,600 - 7,000 24 - 34 477 7664 Medium viscosity active alignment optical bonder for metals, glass, and ceramics in optical and medical devices. Very low shrinkage and water absorption. Withstands stringent thermal cycling. High Performance Metal/Glass/Ceramics Slight Tint 3,000 6,400 - 10,900 83 - 93 18 7731 High strength optical bonder with low shrinkage and water absorption. Designed for active alignment in optical and medical devices. Bonds effectively to metals, glass, and ceramics, enduring stringent thermal cycling. High Performance Metal/Glass/Ceramics Slight Tint 250 8,000 - 10,600 83 - 93 7 7760 Active alignment optical bonder for demanding applications. Very low shrinkage and water absorption. Withstands stringent thermal cycling. Bonds to metals, glass, and ceramics in optical/medical devices. High Performance Metal/Glass/Ceramics Slight Tint 90 8,700 - 10,100 83 - 93…