The Ultimate Guide to UV Curing Adhesive for Glass: Precision, Strength, and Clarity

In the world of modern manufacturing and industrial assembly, the demand for high-strength, aesthetically pleasing, and rapid-bonding solutions has never been higher. Among the most innovative technologies leading this charge is UV curing adhesive glass bonding. Whether you are in the electronics, medical device, furniture, or automotive industry, understanding how UV adhesives interact with glass is essential for achieving superior product quality.

Glass is a unique substrate. It is valued for its transparency, hardness, and chemical resistance. However, these same properties make it challenging to bond using traditional mechanical fasteners or solvent-based glues. UV curing adhesives have revolutionized this process, offering a “liquid-to-solid” transformation in seconds under ultraviolet light, resulting in a bond that is often stronger than the glass itself.

What is UV Curing Adhesive for Glass?

UV curing adhesive for glass is a specialized type of resin—typically acrylic or epoxy-based—that remains in a liquid state until it is exposed to specific wavelengths of ultraviolet light. This light triggers a chemical reaction known as polymerization. Unlike traditional adhesives that dry through evaporation or cure via chemical mixing (like two-part epoxies), UV adhesives cure on demand.

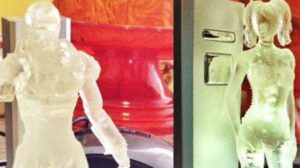

When used on glass, these adhesives are formulated to be optically clear, ensuring that the bond line is invisible to the naked eye. This makes them the preferred choice for applications where aesthetics are just as important as structural integrity. The ability to control the “cure time” allows technicians to align parts perfectly before “locking” them into place with a UV lamp.

The Science of the UV Curing Process

To appreciate why UV curing adhesive for glass is so effective, one must understand the chemistry involved. These adhesives contain photoinitiators. When these molecules are hit by UV light (usually in the 365nm to 405nm range), they decompose and release free radicals or cations. These reactive species then cause the monomers and oligomers in the liquid resin to link together into a cross-linked polymer chain.

This process happens almost instantaneously. In many industrial settings, a full cure can be achieved in 1 to 30 seconds, depending on the intensity of the light source and the thickness of the adhesive layer. Because glass is transparent, it allows the UV light to pass through the substrate and reach the adhesive even in “blind” joints, provided at least one of the substrates is UV-transmissive.

The Importance of Wavelength

Not all UV light is the same. Most glass bonding applications require a wavelength of 365nm. However, some modern glass types are treated with UV-blocking coatings (like those found in automotive windshields or energy-efficient windows). In these cases, specialized adhesives that cure using visible light (blue light) or high-intensity UV-V wavelengths are required.

Key Benefits of Using UV Curing Adhesive for Glass

- Optical Clarity: One of the biggest draws of UV adhesives is their refractive index, which can be matched to glass. This results in a seamless, invisible bond that is critical for displays, lenses, and high-end glass furniture.

- Speed and Efficiency: In high-volume manufacturing, time is money. UV curing eliminates the need for long drying times or “fixturing” periods where parts must be held together for hours.

- Superior Strength: When properly applied, the bond strength often exceeds the cohesive strength of the glass. If the joint is stressed to the point of failure, the glass will usually break before the adhesive bond fails.

- Precision Alignment: Because the adhesive only cures when exposed to light, manufacturers have unlimited time to position the glass components accurately. This reduces waste and improves yield.

- Environmental Resistance: High-quality UV adhesives for glass are designed to resist yellowing, moisture, and thermal cycling, ensuring the bond remains stable for the life of the product.

Common Applications of UV Curing Adhesive Glass Bonding

1. Electronics and Optoelectronics

In the production of smartphones, tablets, and wearable devices, UV adhesives are used to bond touchscreens to frames and to encapsulate sensitive optical sensors. The low-stress curing properties prevent distortion of the glass, which is vital for maintaining display quality.

2. Medical Device Manufacturing

Glass syringes, blood analyzers, and endoscopes often rely on UV-curable adhesives. These adhesives are frequently formulated to meet biocompatibility standards (such as USP Class VI) and can withstand sterilization processes like autoclaving or Gamma irradiation.

3. Glass Furniture and Architectural Design

From glass-to-metal hinges in display cases to the assembly of intricate glass awards and trophies, UV adhesives provide the structural integrity needed without the unsightly look of screws or bolts. This “glass-on-glass” look is a staple of modern interior design.

4. Automotive Industry

UV adhesives are used for bonding rearview mirrors to windshields, assembling sensor brackets, and sealing headlamp assemblies. Their ability to withstand extreme temperature fluctuations and vibrations makes them ideal for the rigorous automotive environment.

Choosing the Right UV Adhesive for Your Glass Project

Not all UV adhesives are created equal. When selecting a product for UV curing adhesive glass applications, consider the following factors:

Viscosity

Viscosity refers to the thickness of the liquid. Low-viscosity adhesives are “water-like” and are designed to “wick” into tight gaps through capillary action. High-viscosity or gel-like adhesives are better for vertical surfaces or when filling larger gaps.

Substrate Compatibility

Are you bonding glass to glass, glass to metal, or glass to plastic? Different formulations are optimized for different materials. For example, bonding glass to stainless steel requires an adhesive that can handle the different rates of thermal expansion between the two materials.

Environmental Exposure

Will the finished product be used outdoors? If so, you need an adhesive with high UV resistance to prevent yellowing and degradation over time. If the product will be exposed to high humidity, a moisture-resistant formulation is essential.

Cure Depth

If you are applying a thick layer of adhesive, you must ensure the UV light can penetrate through the entire volume. Some adhesives are designed for deep-section curing, while others are optimized for thin films.

The Step-by-Step Process for a Perfect Bond

To achieve professional results with UV curing adhesive for glass, follow this rigorous process:

Step 1: Surface Preparation

This is the most critical step. Glass surfaces must be chemically clean. Any oil, fingerprints, or dust will compromise the bond. Use an industrial-grade glass cleaner or isopropyl alcohol (IPA). For high-stress applications, a silane primer may be applied to the glass to enhance chemical adhesion.

Step 2: Adhesive Application

Apply the adhesive to one surface. Avoid creating air bubbles, as these will be visible through the glass and create weak points in the bond. For precision work, use a dispensing needle or an automated dispensing system.

Step 3: Assembly and Alignment

Join the two components. Because the adhesive hasn’t cured yet, you can slide the parts into the perfect position. Use jigs or fixtures if necessary to maintain alignment.

Step 4: The “Tack” Cure

Briefly expose the joint to UV light for a few seconds. This “sets” the adhesive so the parts won’t move, but it still allows for a final inspection. If a mistake is found at this stage, the parts can often still be separated with effort.

Step 5: Full Curing

Expose the bond to the UV light source for the full recommended duration. Ensure that the light reaches all areas of the adhesive. If you are bonding glass to an opaque material like metal, the light must be directed through the glass side.

Step 6: Finishing

Wipe away any uncured “squeeze-out” from the edges using a solvent. Once fully cured, the bond is permanent.

Troubleshooting Common Issues

Yellowing of the Bond Line

This is usually caused by using an adhesive that is not UV-stable or by “over-curing” the adhesive with excessive light intensity or heat. Ensure you are using a high-quality glass-bonding grade and following the manufacturer’s curing schedule.

Bubbles in the Adhesive

Bubbles are often introduced during the dispensing process or by joining the parts too quickly. Slow, controlled application and “wetting out” the surface gradually can prevent air entrapment.

Bond Failure (Delamination)

If the adhesive peels away from the glass, the culprit is usually contamination. Re-evaluate your cleaning process. In some cases, the glass may have a “tin side” (from the float glass manufacturing process) which can affect adhesion; try bonding to the “air side” or using a primer.

The Future of UV Curing Adhesive Glass Technology

As sustainability becomes a priority, the industry is moving toward “green” UV adhesives that are free of VOCs (Volatile Organic Compounds) and require less energy to cure. Additionally, the rise of LED UV curing lamps has changed the game. LED lamps are more energy-efficient, produce less heat (which prevents glass stress), and have a much longer lifespan than traditional mercury vapor lamps.

We are also seeing the development of “dual-cure” adhesives. These products cure with UV light in the visible areas but also have a secondary heat or moisture cure mechanism for “shadowed” areas where light cannot reach. This is particularly useful in complex automotive or electronic assemblies.

Conclusion

UV curing adhesive for glass represents the pinnacle of bonding technology, combining aesthetic perfection with industrial-grade strength. By selecting the right adhesive, preparing your surfaces meticulously, and using the correct UV light source, you can achieve bonds that are durable, clear, and incredibly strong.

Whether you are a small-scale artisan or a large-scale manufacturer, mastering the use of UV adhesives will open up new design possibilities and streamline your production cycles. The “invisible bond” is no longer a secret—it is a standard for excellence in glass assembly.

If you need expert advice on selecting the perfect adhesive for your specific glass application, our technical specialists are ready to help you optimize your process and ensure long-lasting results.

[Contact Our Team](https://shop.blazeasia.com/pages/contact)

Visit [www.blazeasia.com](https://shop.blazeasia.com) for more information.