Mastering TPE Bonding: A Comprehensive Guide to Techniques, Materials, and Industrial Applications

In the world of modern manufacturing, the ability to combine different materials into a single, cohesive component is a game-changer. Thermoplastic Elastomers (TPE) have emerged as some of the most versatile materials in this landscape, bridging the gap between the flexibility of rubber and the processability of thermoplastics. However, the success of any multi-material product often hinges on one critical factor: TPE bonding. Whether you are designing a soft-touch grip for a power tool or a complex medical seal, understanding how to effectively bond TPE to rigid substrates is essential for product durability, aesthetics, and functionality.

TPE bonding is not a one-size-fits-all process. It involves a sophisticated interplay of chemistry, thermodynamics, and mechanical engineering. As industries push for more ergonomic and lightweight designs, the demand for high-strength TPE bonds has skyrocketed. This comprehensive guide explores the various methods of TPE bonding, the challenges of material compatibility, and the best practices for achieving a permanent, industrial-grade bond.

Understanding the Fundamentals of TPE Bonding

To master TPE bonding, one must first understand what makes TPE unique. TPEs are a family of rubber-like materials that can be processed using traditional thermoplastic methods like injection molding and extrusion. They consist of a hard phase (providing structural integrity) and a soft phase (providing elasticity). The challenge in bonding lies in the fact that many TPEs, particularly those based on Polyolefins or Styrenic block copolymers (SEBS), have low surface energy, making them naturally resistant to “sticking” to other materials.

Effective bonding occurs through three primary mechanisms:

- Chemical Bonding: This involves molecular inter-diffusion or the formation of covalent bonds between the TPE and the substrate. This is the strongest type of bond.

- Mechanical Interlocking: This occurs when the molten TPE flows into pores, grooves, or undercuts in the rigid substrate, physically “locking” the two materials together upon cooling.

- Polar Attraction: This involves Van der Waals forces or hydrogen bonding, which are weaker than chemical bonds but contribute to overall adhesion.

Primary Methods of TPE Bonding

Depending on the production volume, part design, and material selection, manufacturers use several distinct methods to achieve TPE bonding. Each has its advantages and limitations.

1. Overmolding (Multi-Shot Injection Molding)

Overmolding is widely considered the gold standard for TPE bonding in high-volume production. This process involves molding a TPE layer directly onto a rigid plastic or metal substrate. There are two main types of overmolding:

- Two-Shot (2K) Molding: This is performed on a specialized machine with two injection units. The rigid substrate is molded first, and while it is still warm, the mold rotates or moves to allow the TPE to be injected over it. The residual heat in the substrate promotes molecular diffusion, resulting in a superior chemical bond.

- Insert Molding: In this process, a pre-molded rigid part is placed into a separate mold, and the TPE is injected around it. While more cost-effective in terms of machinery, it often requires the substrate to be pre-heated to achieve a high-quality bond.

2. Adhesive Bonding

When overmolding is not feasible due to part geometry or low production volumes, adhesive bonding is the go-to solution. However, bonding TPE with adhesives can be tricky because of the material’s low surface energy. Common adhesives used include:

- Cyanoacrylates: Often called “super glues,” these work well with polar TPEs (like TPU) but may require a primer for non-polar TPEs (like SEBS).

- Epoxies and Polyurethanes: These provide high structural strength and environmental resistance but usually require extensive surface preparation.

- Pressure-Sensitive Adhesives (PSAs): Used commonly in gaskets and tapes, these offer a quick bond but lower structural integrity compared to liquid adhesives.

3. Thermal and Ultrasonic Welding

Welding techniques use heat to melt the interface between the TPE and the substrate, allowing them to fuse. Ultrasonic welding uses high-frequency vibrations to generate localized heat. This method is incredibly fast and clean, but it requires the two materials to be chemically compatible (usually meaning they share a similar base polymer). Other methods include hot-plate welding and laser welding, which are increasingly used in automotive lighting and medical device manufacturing.

Material Compatibility: What Sticks to What?

The success of TPE bonding is heavily dependent on the “compatibility” between the TPE and the rigid substrate. Compatibility refers to the ability of the two polymers to mix at the interface and form a strong bond.

TPE to Polypropylene (PP) and Polyethylene (PE)

These are the easiest bonds to achieve because many TPEs (especially TPVs and SEBS-based TPEs) are inherently polyolefin-based. Since they share similar chemical structures, they fuse easily during overmolding without the need for special additives.

TPE to Engineering Plastics (ABS, PC, Nylon)

Bonding TPE to polar engineering plastics like Acrylonitrile Butadiene Styrene (ABS), Polycarbonate (PC), or Polyamide (Nylon/PA) is more complex. Standard TPEs will not bond to these materials naturally. Manufacturers must use modified TPE grades that contain functional groups (like maleic anhydride) designed to react chemically with the polar groups in the engineering plastic.

TPE to Metal

Bonding TPE to metal is almost entirely dependent on mechanical interlocking or the use of specialized primers. Since metal does not melt at TPE processing temperatures, there is no molecular diffusion. To ensure a permanent bond, the metal surface should be roughened (sandblasted) or designed with holes and grooves that the TPE can flow into. [Contact Our Team](https://shop.blazeasia.com/pages/contact) for advice on selecting the right bonding agents for metal-to-TPE applications.

Surface Treatment: Enhancing Adhesion on Difficult Substrates

When chemical compatibility is lacking, surface treatments can “force” a bond by increasing the surface energy of the substrate or the TPE. This is particularly important for secondary bonding processes like gluing or painting.

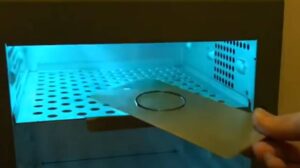

Plasma and Corona Treatment

These treatments involve exposing the surface to an ionized gas or a high-voltage discharge. This process breaks molecular bonds on the surface and introduces oxygen-containing groups, making the surface much more “wettable” and reactive to adhesives.

Flame Treatment

Similar to plasma, flame treatment uses a controlled flame to oxidize the surface. It is a cost-effective method often used in the automotive industry for large parts like bumpers or interior panels before TPE bonding or coating.

Chemical Primers

Primers act as a bridge between the TPE and the substrate. They are typically solvent-based coatings that contain a “tie-layer” polymer. The solvent bites into the substrate, and the tie-layer provides a surface that the TPE can easily bond to.

Design Principles for Successful TPE Bonding

Engineering a part for TPE bonding requires more than just picking the right materials. The physical design of the part plays a massive role in whether the bond will hold up under real-world stress.

1. Maximize Surface Area

The strength of a bond is directly proportional to the area of contact. Designers should maximize the “bond line” wherever possible. Using a “lap joint” is always preferable to a “butt joint” because it provides more surface area and better handles shear forces.

2. Incorporate Mechanical Interlocks

Even if you have a perfect chemical bond, adding mechanical interlocks provides a “safety net.” Design features like “through-holes” (where the TPE flows through the substrate and mushrooms out on the other side) or “dovetails” can prevent delamination even if the chemical bond fails due to environmental exposure.

3. Manage Wall Thickness

In overmolding, the thickness of the TPE layer matters. If the TPE is too thin, it may cool too quickly, preventing it from bonding to the substrate. Conversely, if it is too thick, internal shrinkage stresses might pull the TPE away from the substrate as it cools. A typical TPE overmold thickness ranges from 0.5mm to 3.0mm.

4. Avoid Sharp Corners

Sharp corners act as stress concentrators. When a part is bent or impacted, the stress will focus on these sharp points, often leading to a “peel” failure. Using radii and fillets helps distribute the stress evenly across the bond line.

Troubleshooting Common TPE Bonding Failures

Even with careful planning, bonding issues can arise. Understanding the root cause of failure is the first step toward a solution.

Delamination and Peeling

If the TPE peels off easily, the cause is usually a lack of chemical compatibility or insufficient heat during the overmolding process. Check the melt temperature of the TPE and ensure the substrate is clean and free of mold release agents (which are notorious for killing adhesion).

Bubbling or Voiding at the Interface

This is often caused by moisture. Many substrates, like Nylon, are hygroscopic (they absorb water). If the substrate is not dried properly before overmolding, the moisture turns into steam when hit by the molten TPE, creating bubbles that weaken the bond.

Incomplete Filling

If the TPE doesn’t reach the edges of the bond area, it may be due to low injection pressure or the TPE freezing off too quickly. Increasing the mold temperature or the injection speed can often resolve this.

Industry Applications of TPE Bonding

The ability to bond TPE to rigid materials has revolutionized several key industries:

- Medical Devices: TPE is bonded to rigid plastics to create ergonomic handles for surgical instruments, soft-touch buttons on diagnostic equipment, and seals for syringes. The bond must be able to withstand sterilization processes like autoclaving.

- Automotive: From weatherstrips and window seals to interior “soft-touch” dashboards and cup holder liners, TPE bonding is essential for reducing Noise, Vibration, and Harshness (NVH) while improving aesthetics.

- Consumer Electronics: Think of your smartphone case or your electric toothbrush. These often feature TPE overmolded onto Polycarbonate to provide impact protection and a non-slip grip.

- Industrial Tools: Power drills and wrenches use TPE bonding to provide vibration dampening and comfort for the user, requiring bonds that can withstand heavy grease and mechanical abuse.

The Future of TPE Bonding

As we look toward the future, the focus of TPE bonding is shifting toward sustainability and smart materials. We are seeing the rise of Bio-based TPEs that offer the same bonding performance as petroleum-based versions but with a lower carbon footprint. Additionally, the development of “recyclable-by-design” multi-material parts is a growing trend. This involves creating bonds that are strong during the product’s life but can be “triggered” to release at the end of life, allowing for easier separation and recycling of the TPE and the rigid plastic.

Furthermore, advancements in 3D printing (Additive Manufacturing) are opening new doors for TPE bonding. Multi-material 3D printers can now print a rigid core and a soft TPE shell simultaneously, allowing for rapid prototyping of overmolded parts without the need for expensive injection molds.

Conclusion

TPE bonding is a sophisticated process that requires a deep understanding of material science and precision engineering. By selecting the right bonding method—be it overmolding, adhesives, or welding—and ensuring chemical compatibility between the TPE and the substrate, manufacturers can create high-performance products that meet the rigorous demands of today’s market. Whether you are aiming for better ergonomics, improved sealing, or enhanced durability, mastering the art of the bond is your key to success.

If you are facing challenges with your current TPE application or are starting a new project that requires expert material selection, our team is here to help. We provide technical support and high-quality materials tailored to your specific bonding requirements.

Visit [www.blazeasia.com](https://shop.blazeasia.com) for more information.