Ultra-high power UV LED curing systems: Faster cure times, enhanced bond strength, and energy efficiency. Discover how Incure’s UV curable adhesives and equipment optimize manufacturing processes.

In today’s fast-paced manufacturing landscape, efficiency and precision are paramount. For professionals seeking to streamline production and achieve superior bonding results, ultra-high power UV curing LED systems are revolutionizing the industry. This blog explores the benefits of these advanced systems and how Incure’s comprehensive line of adhesives and equipment can empower your projects.

The Power of Ultra-High Power UV LED Curing

Traditional UV curing methods often fall short when dealing with complex materials or demanding production schedules. Ultra-high power UV LED systems overcome these limitations by delivering:

- Faster Cure Times: Increased irradiance translates to significantly reduced curing times, boosting throughput and minimizing downtime.

- Deeper Penetration: The intense UV light penetrates deeper into adhesives and coatings, ensuring thorough and consistent curing, even in shaded areas or with thick layers.

- Enhanced Bond Strength: Complete curing results in stronger, more durable bonds, leading to higher product quality and reliability.

- Energy Efficiency: LED technology consumes significantly less energy than traditional arc lamps, reducing operating costs and environmental impact.

- Precise Control: LED systems offer precise control over intensity and wavelength, allowing for optimized curing processes for various materials.

- Extended Lifespan: LED emitters boast a significantly longer lifespan compared to traditional bulbs, minimizing maintenance and replacement costs.

- Reduced Heat Generation: LED systems produce less heat, protecting heat-sensitive substrates and minimizing thermal stress.

Applications Across Industries

The versatility of ultra-high power UV LED curing systems makes them ideal for a wide range of applications:

- Electronics Manufacturing: Bonding components, encapsulating sensitive electronics, and conformal coating.

- Medical Device Manufacturing: Assembling medical devices, bonding catheters, and curing biocompatible adhesives.

- Automotive Manufacturing: Bonding automotive components, sealing headlights, and curing coatings.

- Aerospace Manufacturing: Bonding structural components, sealing aircraft windows, and curing composite materials.

- Optical Bonding: Bonding lenses, prisms, and other optical components with high precision.

- General Assembly: Quickly curing adhesives on many different types of products.

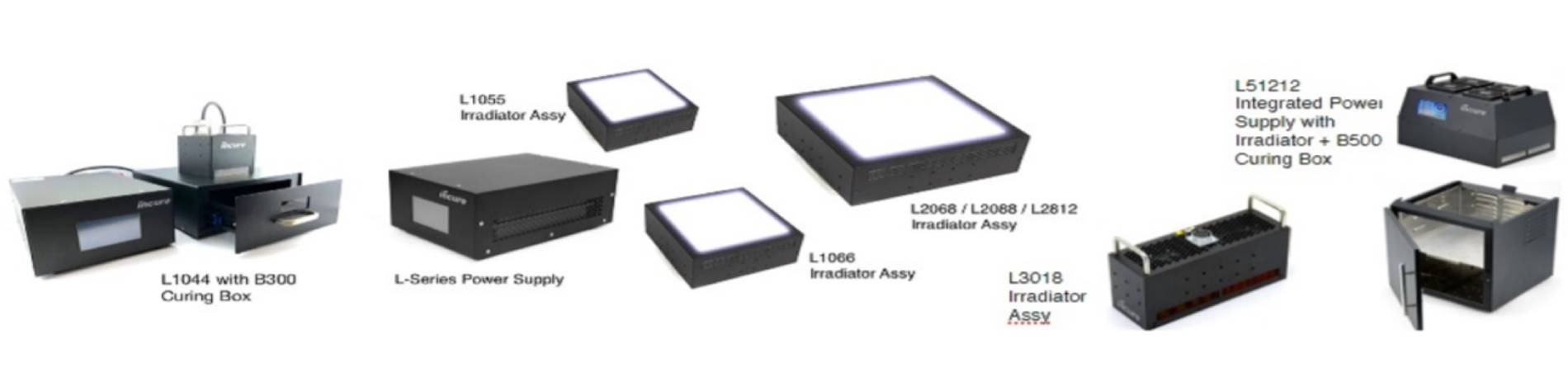

| Configuration | L1044 | L1055 | L1066 | L2068 | L2088 | L2812 | L3018 | L51212 | |||||||||||

| Type of Lamp | LED Flood, Programmable | ||||||||||||||||||

|

Intensity in mW/cm2 (Measured with EIT Power Puck Distance from Lamp Base) |

UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | |||

| @0.5 | 2750 | 139 | 2200 | 112 | 1930 | 91 | 1650 | 70 | 1380 | 59 | 1240 | 56 | 8750 | 1380 | 70 | ||||

| @1.0 | 2540 | 127 | 2040 | 105 | 1780 | 87 | 1530 | 69 | 1270 | 58 | 1150 | 55 | 8000 | 1270 | 64 | ||||

| @1.5″ | 2420 | 120 | 1940 | 99 | 1700 | 84 | 1460 | 68 | 1210 | 57 | 1090 | 54 | 7500 | 1210 | 60 | ||||

| @2.0″ | 2370 | 116 | 1900 | 93 | 1660 | 81 | 1430 | 67 | 1190 | 56 | 1070 | 53 | 7200 | 1190 | 58 | ||||

| @2.5″ | 2260 | 111 | 1810 | 87 | 1590 | 78 | 1360 | 66 | 1130 | 55 | 1020 | 52 | 6900 | 1130 | 56 | ||||

| @3.0″ | 2070 | 101 | 1660 | 82 | 1450 | 75 | 1250 | 65 | 1040 | 54 | 940 | 51 | 6750 | 1040 | 51 | ||||

| @4.0″ | 1550 | 82 | 1240 | 77 | 1090 | 72 | 930 | 64 | 780 | 53 | 700 | 50 | 6600 | 780 | 41 | ||||

| Intensity Adjustment | LED Controller | ||||||||||||||||||

| Available Wavelengths | 365 , 395, 405 | ||||||||||||||||||

| Working Distance | 1.5” – 4.0” | ||||||||||||||||||

| Expected Bulb Life* | > 20,000 hrs | ||||||||||||||||||

| Intensity Decay over Life | 20% | ||||||||||||||||||

| Static Uniformity @ 2.0” | 0.78 | ||||||||||||||||||

| Dynamic Uniformity @ 3.0” | 0.90 | ||||||||||||||||||

| Curing Area | 4” x 4” | 5” X 5” | 6” X 6” | 6” X 8” | 8” X 8” | 8” X 12” | 1” X 8” | 12” X 12” | |||||||||||

| Curing Box Adjustable Heights (optional purchase) | 3.5” Max Distance | ||||||||||||||||||

| Temperature Management | Forced Air with Standby Mode | ||||||||||||||||||

| Power Input | 100-240V, 50/60Hz, Auto-Ranging | ||||||||||||||||||

| External Control Port | LCD Programmable Panel | ||||||||||||||||||

| Ordering Part Number | L1044-365 L1044-395 L1044-405 | L1055-365 L1055-395 L1055-405 | L1066-365 L1066-395 L1066-405 | L2068-365 L2068-395 L2068-405 | L2088-365 L2088-395 L2088-405 | L2812-365 L2812-395 L2812-405 | L3018-365 L3018-395 L3018-405 | L21212-365 L21212-395 L21212-405 | |||||||||||

| Irradiator Dimension / Weight | 5.1” x 5.1” x 6.4” (4.6 lb) | 6.1” x 6.1” x 6.4” (5.9 lb) | 7.1” x 7.1” x 6.4” (5.9 lb) | 7.6” x 9.1” x 6.4” (9.2 lb) | 9.9” x 9.9” x 3.95” (15.5 lb) | 9.1” x 18.1” x 6.4” (18.4 lb) | 10.3” x 3.6” x 4.0” (5.5 lb) | 14.7” x 14.2” x 21.6” (78 lb) | |||||||||||

| Controller Dimension / Weight | 12.9” x 5.2” x 9” (17.1 lb) | 13” x 9.1” x 5.2” (14.5 lb) | |||||||||||||||||

| Curing Drawer / Box(Optional Purchase,Unless Specified) | B300 | Request For More Information | Included | ||||||||||||||||

| Curing Drawer / Box Dimension | 12” x 12” x 5.5” | 12” x 12” x 5.5” | 12” x 12” x 5.5” | 12” x 12” x 5.5” | 12” x 12” x 5.5” | ||||||||||||||

| Interlock Safety Feature | Integrated When Mounted on B300 Curing Drawer | ||||||||||||||||||

| C9000 TM Conveyor Mounting | Yes | No | Not Applicable | ||||||||||||||||

See how Incure UV LED flood lamps provide broad, uniform coverage – visit Blaze’s showroom and experience the difference today!