UV Resin Bonding: A Comprehensive Guide

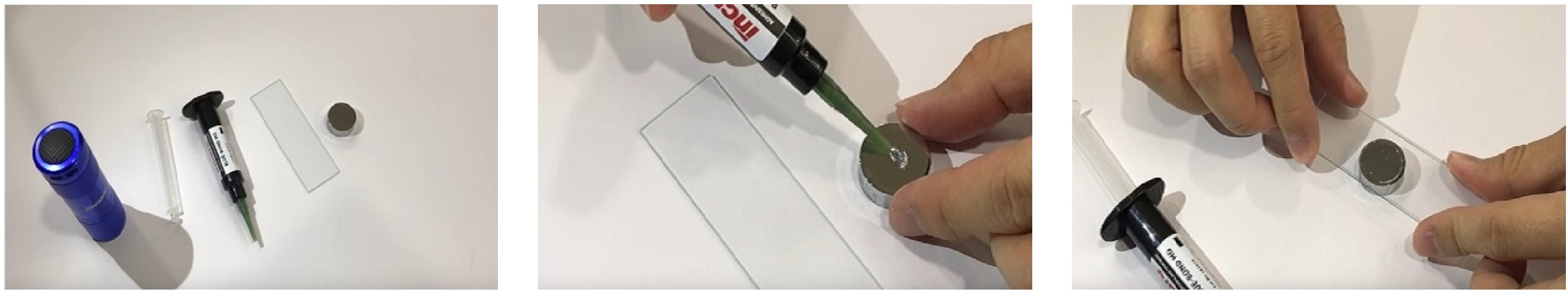

Introduction UV resin kits have revolutionized the way we bond materials, offering a rapid and efficient alternative to traditional adhesives. These versatile kits are essential tools for DIY enthusiasts, crafters, and professionals alike, providing a reliable solution for a wide range of bonding needs. This comprehensive guide will explore the benefits of UV resin bonding, guide you through the usage process, and provide valuable tips for achieving optimal results. What is UV Resin Bonding? UV resin bonding utilizes a specially formulated liquid resin that undergoes a rapid curing process when exposed to ultraviolet (UV) light. Unlike traditional adhesives that require extended drying times, UV resin cures in minutes, significantly accelerating project completion. Key Features of UV Resin Bonding: Rapid Curing: Experience fast bonding times, significantly reducing project completion times. Crystal Clear Finish: Provides a transparent and aesthetically pleasing finish, ideal for jewelry making, decorative projects, and repairs. Versatility: Bonds effectively to a wide range of materials, including glass, metal, wood, plastic, and ceramics. Strong and Durable Bonds: Creates robust bonds that are resistant to water, heat, and many chemicals. Precision Application: Allows for precise and controlled application of the resin, minimizing waste and ensuring clean results. How Does UV Resin Bonding Work? UV resin is a liquid polymer that remains in a fluid state until exposed to UV light. Upon exposure, the resin undergoes a photochemical reaction, rapidly polymerizing into a solid, durable bond. The curing process can be completed within minutes, depending on the intensity of the UV light and the thickness of the resin layer. Step-by-Step Guide to UV Resin Bonding Surface Preparation: Clean and prepare the surfaces to be bonded. Remove any dirt, dust, oil, or other contaminants that may interfere with adhesion. Resin Application: Apply a thin, even layer of resin to one or both surfaces. Join the Materials: Press the materials together firmly to ensure proper contact and distribute the resin evenly. UV Curing: Expose the bonded area to the UV light for the recommended time. Most resins cure within 1-3 minutes under a standard UV lamp. Finishing Touches: After curing, trim or sand any excess resin for a smooth and professional finish. Benefits of UV Resin Bonding Speed and Efficiency: Significantly reduces project completion times compared to traditional adhesives. Precision and Control: Allows for precise application and minimizes the risk of excess adhesive. Crystal Clear Finish: Provides a visually appealing and transparent bond. Durable and Long-Lasting: Creates strong and durable bonds that are resistant to various environmental factors. Versatility: Suitable for a wide range of applications, from jewelry making and crafting to repairs and industrial projects. Applications of UV Resin Bonding: Jewelry Making: Creating intricate jewelry designs, including pendants, rings, and earrings. Crafting and DIY Projects: Bonding various materials for decorative items, scrapbooking, and model making. Repairs: Fixing broken glass, ceramics, and other delicate items. Industrial Applications: Used in electronics, automotive, and other industries for bonding components and creating durable assemblies. Tips for Optimal Results Work in a Well-Lit Area: Ensure adequate ambient light…