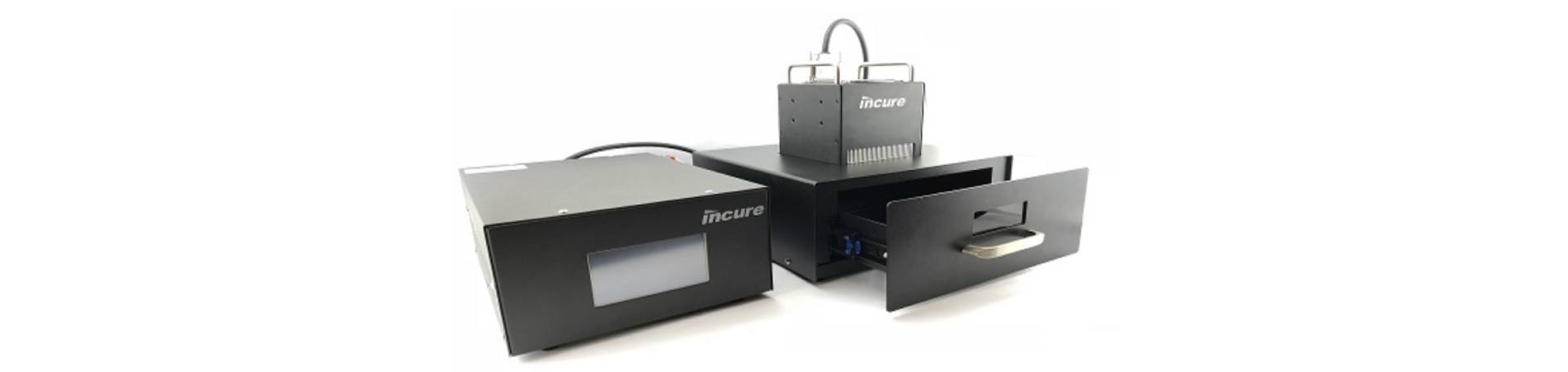

L21212 UV LED Flood Lamp: High-Power Curing for Large-Scale Applications

Reduce curing costs without sacrificing performance. The L21212 UV LED Flood Lamp offers a lower cost per joule and high-power output for large-scale applications. Explore wavelength options and integration possibilities.Boost Production Efficiency and Lower Costs with Unparalleled Curing Power and Coverage. In today's fast-paced manufacturing world, efficient and powerful light-curing solutions are essential for large-scale applications. The L21212 UV LED Flood Lamp (available in 365nm, 385nm, and 405nm) is a game-changer, delivering exceptional curing power, broad coverage, and a lower cost per joule. Discover how the L21212 can revolutionize your light-curing processes. Why Choose the L21212 UV LED Flood Lamp for Large-Scale Curing? Lower Cost per Joule: Powered by 144 high-power LEDs, the L21212 maximizes light output and minimizes energy consumption, resulting in significant long-term cost savings. Unmatched Intensity and Curing Area: Boasting over 2,200 mW/cm² of intensity across a massive 12" x 12" curing area, the L21212 offers the highest power and coverage in its class, perfectly suited for demanding large-scale applications. Versatile Wavelength Options: Choose from 365nm, 385nm, or 405nm wavelengths to precisely match your UV/Visible light-curable adhesives and coatings, ensuring optimal performance across various manufacturing processes. Modular Design for Ultimate Flexibility: Use the L21212 as a standalone unit in workshops or labs, seamlessly integrate it into UV chambers for controlled curing, or mount it on Incure C9000 UV Conveyor Systems for high-volume production lines. User-Friendly Control: Operate the L21212 effortlessly via footswitch or PLC control, enabling programmable curing modes and precise process management. Applications of the L21212 UV LED Flood Lamp: High-Volume Manufacturing: Ideal for efficient curing of large products or multiple items simultaneously in high-volume production environments. Controlled UV Chamber Curing: Integrate seamlessly with UV chambers for controlled curing of large, light-sensitive materials. Streamlined Conveyor System Integration: Maximize throughput for large items by mounting the L21212 on Incure C9000 UV Conveyor Systems for continuous production. Oversized Product Curing: Effectively cure large objects or wide surfaces coated with UV/Visible light-curable adhesives, sealants, or coatings. Large Panel Curing: Perfect for curing large panels used in diverse industries, including signage, displays, and solar panel manufacturing. Selecting the Right L21212 UV LED Flood Lamp: Choosing the optimal L21212 configuration depends on several key factors: Wavelength: Select the wavelength (365nm, 385nm, or 405nm) that best matches your specific light-curable material. Application Needs: Consider your production volume, object dimensions, and desired level of integration (standalone vs. conveyor system integration). Control Requirements: Determine the necessary level of control (footswitch vs. PLC with programmable curing modes) for optimal process management. Ventilation: Due to the L21212's high intensity, ensure adequate ventilation in your workspace. Maintenance: While LEDs offer a longer lifespan, factor in any potential maintenance requirements. L21212 UV LED Flood Lamp Configuration Specifications Type of Lamp LED Flood Peak Intensity, Distance from Lamp Base, (mW/cm2) @1.0" @1.5" @2.0" @2.5" 1,270 1,210 1,190 1,130 Intensity Adjustment YES Optional Wavelengths 365, 395, 405 Working Distance 1.5"-3" Expected Bulb Life >20000 hrs Intensity Decay Over Life 20% Curing Area 12" x 12"…