L2088 UV LED Flood Lamp: High-Intensity Curing for Diverse Applications

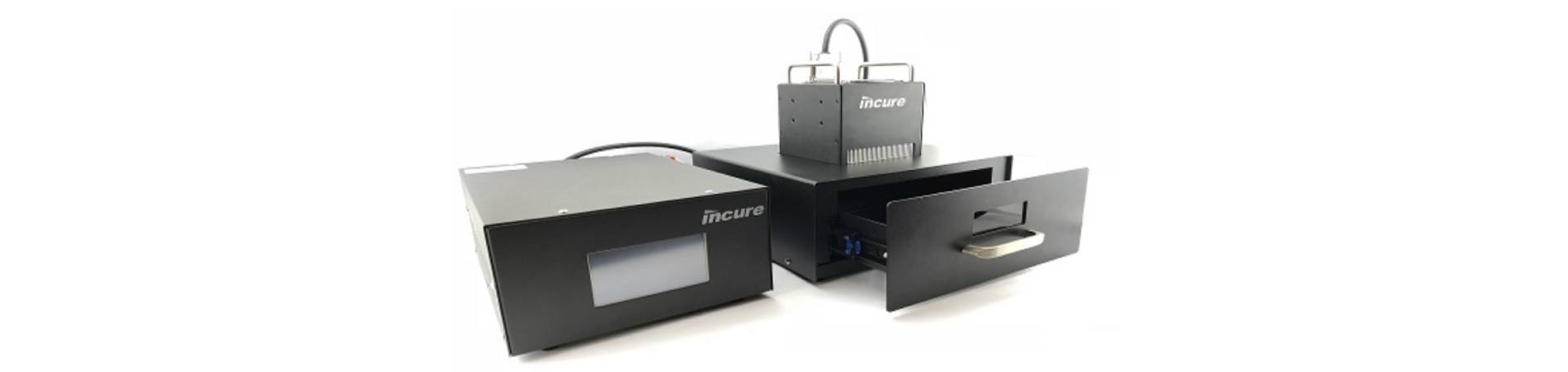

Click Here for Specifications Maximize efficiency in your light-curing processes with the L2088. High power, a large curing area, and a lower cost per joule make it the ideal solution.Maximize Efficiency and Versatility in Your Light-Curing Processes. In the world of light-curable materials, manufacturers demand power, efficiency, and versatility. The L2088 UV LED Flood Lamp (available in 365nm, 385nm, and 405nm) delivers a unique combination of high intensity, a substantial curing area, and modular design to optimize your light-curing operations. Discover how the L2088 can elevate your production. Why Choose the L2088 UV LED Flood Lamp? Lower Cost per Joule: 144 high-power LEDs ensure efficient light output, reducing energy consumption and operational costs. High Intensity and Large Curing Area: Over 1,300 mW/cm² of intensity across an 8" x 8" curing area provides powerful and effective curing for larger surfaces. Versatile Wavelength Options: Choose from 365nm, 385nm, or 405nm wavelengths to match your specific UV/Visible light-curable adhesives and coatings. Modular Design for Flexibility: Use the L2088 as a standalone unit, integrate it into UV chambers, or mount it on Incure C9000 UV Conveyor Systems for seamless high-volume production. User-Friendly Control: Operate easily via footswitch or PLC control, enabling programmable curing modes and precise process management. Applications of the L2088 UV LED Flood Lamp: High-Volume Production: Ideal for efficient curing in high-volume manufacturing, ensuring consistent results for larger products. Controlled UV Chamber Curing: Integrate seamlessly with UV chambers for controlled curing of light-sensitive materials. Streamlined Conveyor System Integration: Maximize throughput by mounting the L2088 on Incure C9000 UV Conveyor Systems. Diverse Curing Applications: Effectively cures a wide range of UV/Visible light-curable materials, including adhesives for assembly, bonding, and encapsulation, and coatings for protection, sealing, or enhancement. Prototyping and Small Batch Production: Adaptable for curing applications in prototyping and small-batch environments. Selecting the Right L2088 UV LED Flood Lamp: Consider these factors when choosing the optimal L2088 configuration: Wavelength: Select the wavelength (365nm, 385nm, or 405nm) that matches your light-curable material. Application Needs: Evaluate your production volume and desired level of integration (standalone vs. conveyor system). Curing Area Requirements: Ensure the 8" x 8" curing area is suitable for your product size. Control Requirements: Determine the necessary level of control (footswitch vs. PLC). Maintenance: While LEDs have a long lifespan, consider potential maintenance needs. L2088 UV LED Flood Lamp Configuration Specifications Type of Lamp LED Flood Peak Intensity, Distance from Lamp Base, (mW/cm2) @1.0" @1.5" @2.0" @2.5" 1,530 1,460 1,430 1,360 Intensity Adjustment YES Optional Wavelengths 365, 395, 405 Working Distance 1.5"-3" Expected Bulb Life >20000 hrs Intensity Decay Over Life 20% Curing Area 8" x 8" Curing Box with Interlock Safety Feature(optional) B300 or B500 with Adapter Plate Curing Box Adjustable Heights 3.5" Temperature Management Forced Air with Louvers Power Input 100-240V 50/60Hz Auto-Ranging External Control Port LCD Programmable Panel Light Source Dimension Power Supply Dimension Curing Box Dimension 9.1"x 9.1"x 6.3" 13"x 5.1"x 9"…