Seal the Deal: Light-Curable Form-In-Place (FIP) & Cure-In-Place (CIP) Gaskets for Industrial Assembly

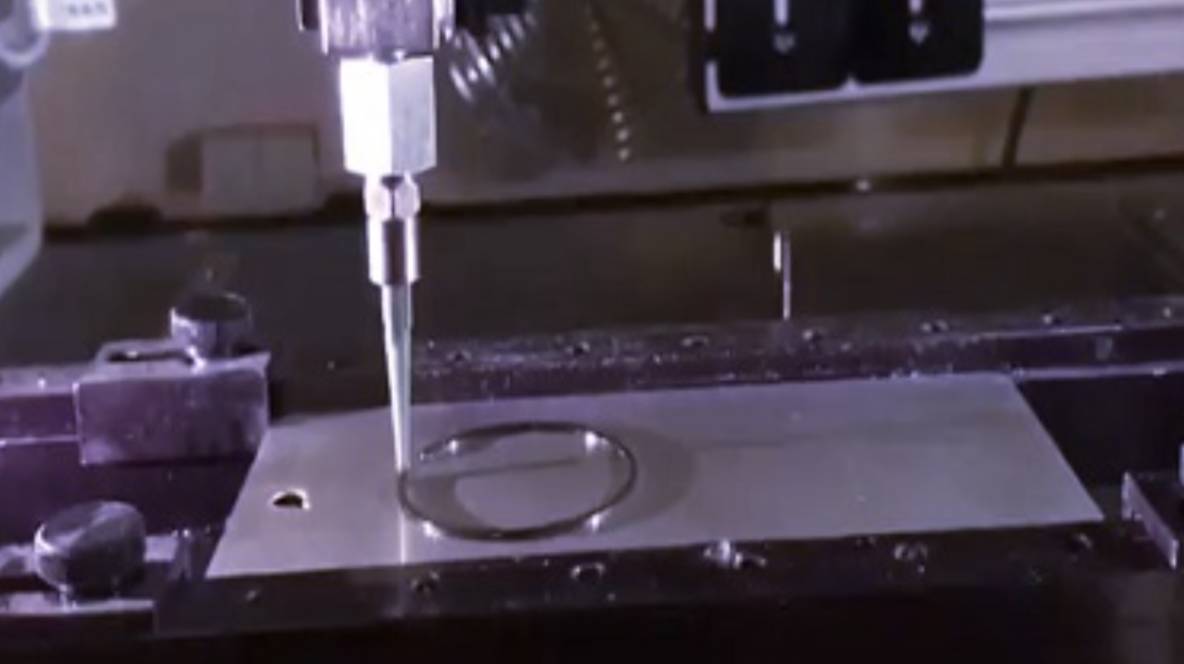

In the fast-paced world of industrial assembly, efficiency and reliability reign supreme. Traditional gasketing methods, like pre-cut gaskets and messy adhesives, can be time-consuming and prone to errors. Enter Light-Curable Form-In-Place (FIP) & Cure-In-Place (CIP) Gaskets – a revolutionary solution that streamlines assembly processes and ensures secure, leak-proof seals. This blog delves into the world of light-curable FIP/CIP gaskets, exploring their functionalities, advantages, and diverse applications in industrial settings. What are Light-Curable FIP/CIP Gaskets? Light-Curable FIP/CIP gaskets are innovative liquid sealants that eliminate the need for pre-cut gaskets. Here's what sets them apart: On-Demand Dispensing: The liquid form allows for precise application directly onto the assembly surfaces, eliminating the need for pre-cut gaskets and minimizing waste. Rapid Curing: Exposure to UV light triggers rapid polymerization, creating a strong, durable seal within seconds or minutes, significantly reducing assembly time. Conformable Sealing: The liquid form fills even the most intricate gaps and contours, ensuring a tight and reliable seal. Versatility: Available in various formulations to adhere to different materials and withstand diverse environmental conditions. Self-Leveling Properties: Certain FIP/CIP gaskets self-level, simplifying application and ensuring a uniform seal thickness. Benefits of Light-Curable FIP/CIP Gaskets Light-Curable FIP/CIP gaskets offer numerous advantages over traditional gasketing methods: Increased Efficiency: On-demand application and rapid curing significantly reduce assembly times and labor costs. Improved Precision: Precise dispensing eliminates misalignment issues common with pre-cut gaskets, leading to more reliable seals. Reduced Waste: Eliminates the need for pre-cut gaskets and minimizes the risk of incorrect size selection, reducing material waste. Enhanced Design Flexibility: FIP/CIP gaskets can be applied to complex geometries, offering greater design freedom compared to pre-cut options. Durable and Leak-Proof Seals: Cured FIP/CIP gaskets form strong, long-lasting seals that resist various environmental conditions, minimizing the risk of leaks. Applications for Light-Curable FIP/CIP Gaskets The versatility and efficiency of FIP/CIP gaskets make them ideal for a wide range of industrial assembly applications: Electronics Manufacturing: Seal enclosures, protect delicate components from dust and moisture. Automotive Assembly: Securely seal engine components, lights, and other parts. Appliance Manufacturing: Create leak-proof seals in appliances like refrigerators, dishwashers, and washing machines. Medical Device Assembly: Ensure secure and sterile seals in medical devices. Aerospace Applications: Withstand demanding environments and create reliable seals in aerospace components. Choosing the Right Light-Curable FIP/CIP Gasket Selecting the optimal FIP/CIP gasket requires considering several factors: Substrate Compatibility: Ensure the chosen gasket material adheres well to the specific surfaces being sealed. Environmental Conditions: Select a gasket formulation that can withstand the expected temperature, pressure, and chemical exposure. Desired Seal Characteristics: Consider factors like flexibility, compression set, and chemical resistance based on the application needs. Curing Speed: Choose a curing speed that aligns with your production line throughput for optimal efficiency. Application Method: Determine if manual or automated dispensing is required, and select a FIP/CIP gasket with the appropriate viscosity. Embrace Efficiency and Reliability with Light-Curable FIP/CIP Gaskets Light-Curable FIP/CIP gaskets offer a game-changing solution for industrial assembly. Their on-demand application, rapid curing, and conformable sealing capabilities streamline assembly processes and ensure…