High-Power LED Curing for Advanced Manufacturing: Unveiling the L1044

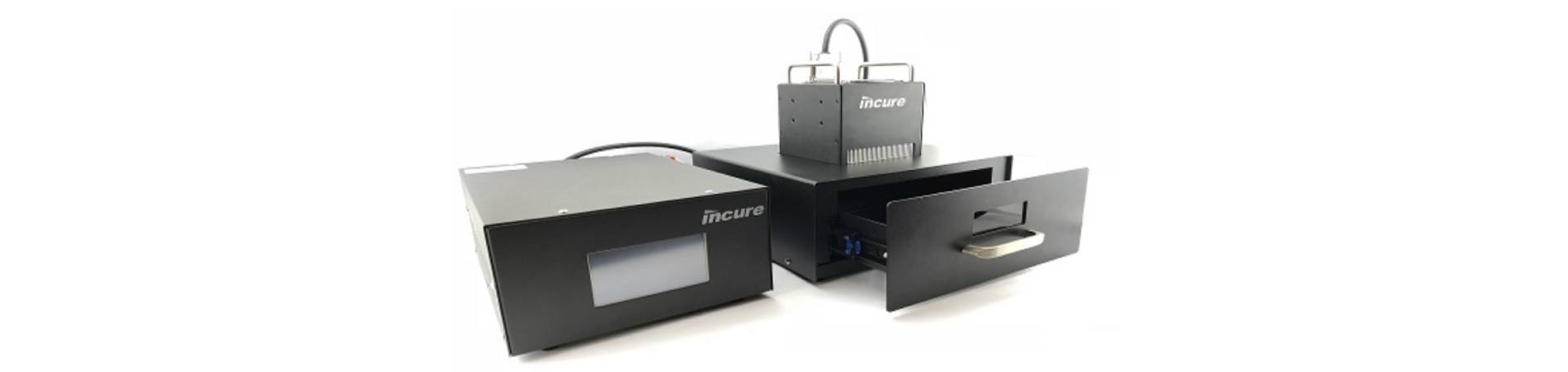

The Incure L1044 LED Curing System offers manufacturers an efficient and cost-effective solution for light curing. Available in 365nm, 385nm, and 405nm configurations, it provides high intensity, versatility, and affordability. Ideal for small and large-scale production, it caters to various applications, including adhesive curing, coating applications, and electronics manufacturing.Introduction: Manufacturers seeking efficient and cost-effective light-curing solutions can find a powerful ally in the Incure L1044 LED Curing System. Available in 365nm, 385nm, and 405nm configurations, this system offers a compelling combination of high intensity, versatility, and affordability. Let's explore the advantages, applications, and key considerations for choosing the L1044 to elevate your production processes. Advantages of the Incure L1044 LED Curing System: Lower Cost per Joule: Utilizing 144 high-power LEDs, the L1044 delivers exceptional light output while consuming less energy, resulting in cost savings over time. High Intensity and Coverage: Achieve superior curing power with over 2,200 mW/cm2 intensity across a 4" x 4" curing area. Versatile Wavelength Options: Cater to a wide range of light-curable materials with 365nm, 385nm, and 405nm configurations. Modular Design: Adapt to various production needs with standalone operation for small-scale curing or integration into UV chambers and conveyor systems for high-volume manufacturing. User-Friendly Control: Operate with ease using a footswitch or PLC control, enabling programmable curing modes for enhanced process control. Applications of the Incure L1044 LED Curing System: Small-Scale Manufacturing: Ideal for workshops, labs, and prototyping environments where standalone operation is preferred. Large-Scale Production: Integrate seamlessly into UV chambers or Incure C9000 UV Conveyor Systems for efficient curing in high-volume production lines. Adhesive Curing: Cure a wide range of light-curable adhesives used in assembly, bonding, and encapsulation applications. Coating Applications: Effectively cure UV/Visible light-curable coatings for protection, sealing, or enhancing product properties. Electronics Manufacturing: Achieve precise curing of adhesives and coatings essential in electronics assembly. Choosing the Right L1044 LED Curing System: Consider these factors when selecting the optimal L1044 configuration: Wavelength: Choose the wavelength that matches your light-curable material (365nm, 385nm, or 405nm). Application Needs: Evaluate production volume and desired integration level (standalone or conveyor system). Control Requirements: Determine the necessary control level (footswitch or PLC with programmable modes). Maintenance Needs: While LEDs offer longevity, factor in potential maintenance requirements. L1044 UV LED Flood Lamp Configuration Specifications Type of Lamp LED Flood Peak Intensity, Distance from Lamp Base, (mW/cm2) @1.0" @1.5" @2.0" @2.5" 2,540 2,420 2,370 2,260 Intensity Adjustment YES Optional Wavelengths 365, 395, 405 Working Distance 1.5"-3" Expected Bulb Life >20000 hrs Intensity Decay Over Life 20% Curing Area 4" x 4" Curing Box with Interlock Safety Feature(optional) B300 or B500 with Adapter Plate Curing Box Adjustable Heights 3.5" Temperature Management Forced Air with Louvers Power Input 100-240V 50/60Hz Auto-Ranging External Control Port LCD Programmable Panel Light Source Dimension Power Supply Dimension Curing Box Dimension 5.1"x 5.1"x 6.3" 13"x 5.1"x 9" Ordering Part Number L1044-365, L1044-395, L1044-405 Conclusion: The…